Devulcanization Without Depolymerization

Transforming scrap rubber into virgin synthetic rubber for less than it costs to produce natural virgin rubber with the same industry applications.

Real World Circular Economy

Customized Production Methods

Internationally Patented Process

ENVIRONMENTAL

WASTE

(CAGR) 2018 – 2025

IN US$ BY 2025

FEEDSTOCK

PROCESS

CUSTOMERS

THAT CAN BE ECONOMICALLY USED BY ORIGINAL MANUFACTURERS

ULTRASONIC DEVULC

MICROWAVE ENERGY

MICROBIOLOGICAL DEVULC

THERMAL WITH CHEMICALS

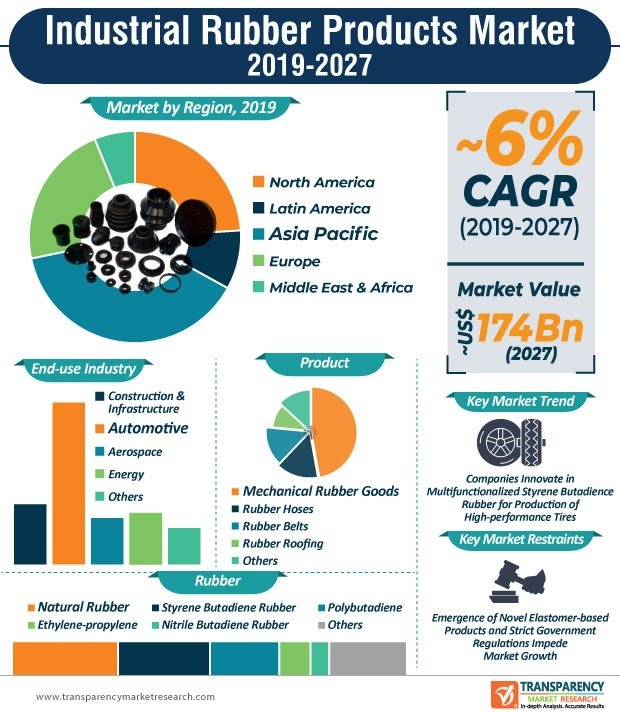

The global industrial rubber products market is expected to grow at a healthy CAGR of 6% during the forecast period of 2019 to 2027. According to product type, the global industrial rubber products market is leading by mechanical goods. It is dominating the market as it held 50% of the share in the market during 2018. It is expected to rise significantly during the forecast period. Asia Pacific among all other regions is leading the market. It held one third of the shares in market during 2018 and is expected to lead the market during the forecast period.

Rise in Demand from End Users to Boost the Market

Reclaimed Rubber Gains Widespread Application in Construction and Automotive Industries

Environment Conservation to Boost Demand

Styrene Butadiene rubber (SBR) is anticipated to dominate the global industrial rubber products market with the second-highest production amongst all rubber types, estimated to reach an output of ~7,500 kilo tons by the end of 2027. Hence, manufacturers are innovating new synthetic rubber solutions to improve tire technology.

- Security:

- Convertible Promissory Note / SAFE

- Amount:

- Up to $1,500,000

- Annual Interest:

- 12% beginning at funding

- Qualified Conversion:

- 20% to the next Financial Round

- Note Conversion at Maturity:

- $25,000,000 Valuation

Rubber Devulc Samples

Marketing Campaigns